INERT EXTINGUISHING GAS

MAINTENANCE, INSPECTION AND CERTIFICATION OF INERT GAS FIRE SUPPRESSION SYSTEMS

AND THE REFILLING AND TOPPING UP OF INERT GAS CYLINDERS

IS YOUR INERT GAS FIRE SUPPRESSION SYSTEM DUE FOR AN INSPECTION?

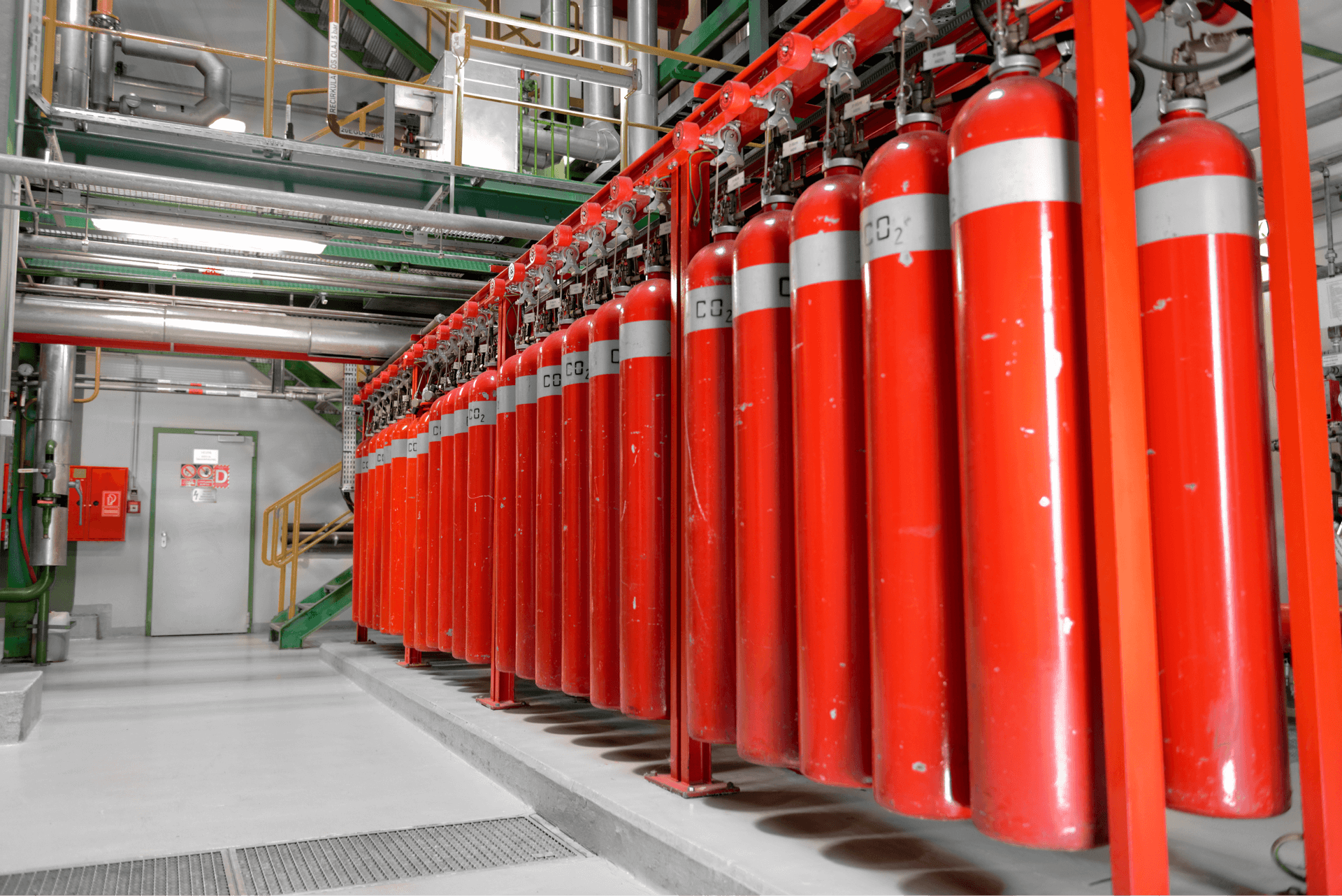

Inert gas fire suppression systems are often used in the shipping, offshore and (petro)chemical sectors. These fire suppression systems are used when foam or water extinguishing is not a suitable option due to the collateral damage caused by these methods. Inert gas fire suppression systems, like other fire-extinguishing systems, are subject to strict safety regulations. Wondering whether your inert gas fire suppression system meets these regulations? Use our inspection to find out!

Kenbri Fire Fighting is the place to go for advice, inert gas refills, and the maintenance and inspection of inert gas fire suppression systems. That way, you know what standards to meet and whether you are prepared for any calamities.

WHEN TO USE INERT GAS FOR FIRE SUPPRESSION?

Inert gas is used when water or foam are not suitable as an extinguishing agent due to the collateral damage they cause. Take, for example, water damage in engine rooms in ships and oil rigs, or damage to electrical equipment in computer rooms. If, in case of a fire, a room is filled with inert gas, this gas ensures the fire is extinguished. This fire suppression method helps keep the collateral damage to a minimum.

TYPES OF INERT GAS

Inert gases are available in various types, each with their own fire-suppressing properties. There are inert gases that displace oxygen and thus smother the fire. Then there are inert gases that act as a negative catalyst. They take away energy from the fire source, disrupting the combustion process. The fire cannot survive in these conditions.

WHY SHOULD AN INERT GAS FIRE SUPPRESSION SYSTEM BE INSPECTED?

Just like any other extinguishing system, an inert gas fire suppression system needs to be inspected regularly. This inspection is mandatory, and should be performed once a year. After all, you want to be sure your fire suppression system is functioning properly. This reduces the damage suffered in case of a calamity and saves you a lot of trouble.

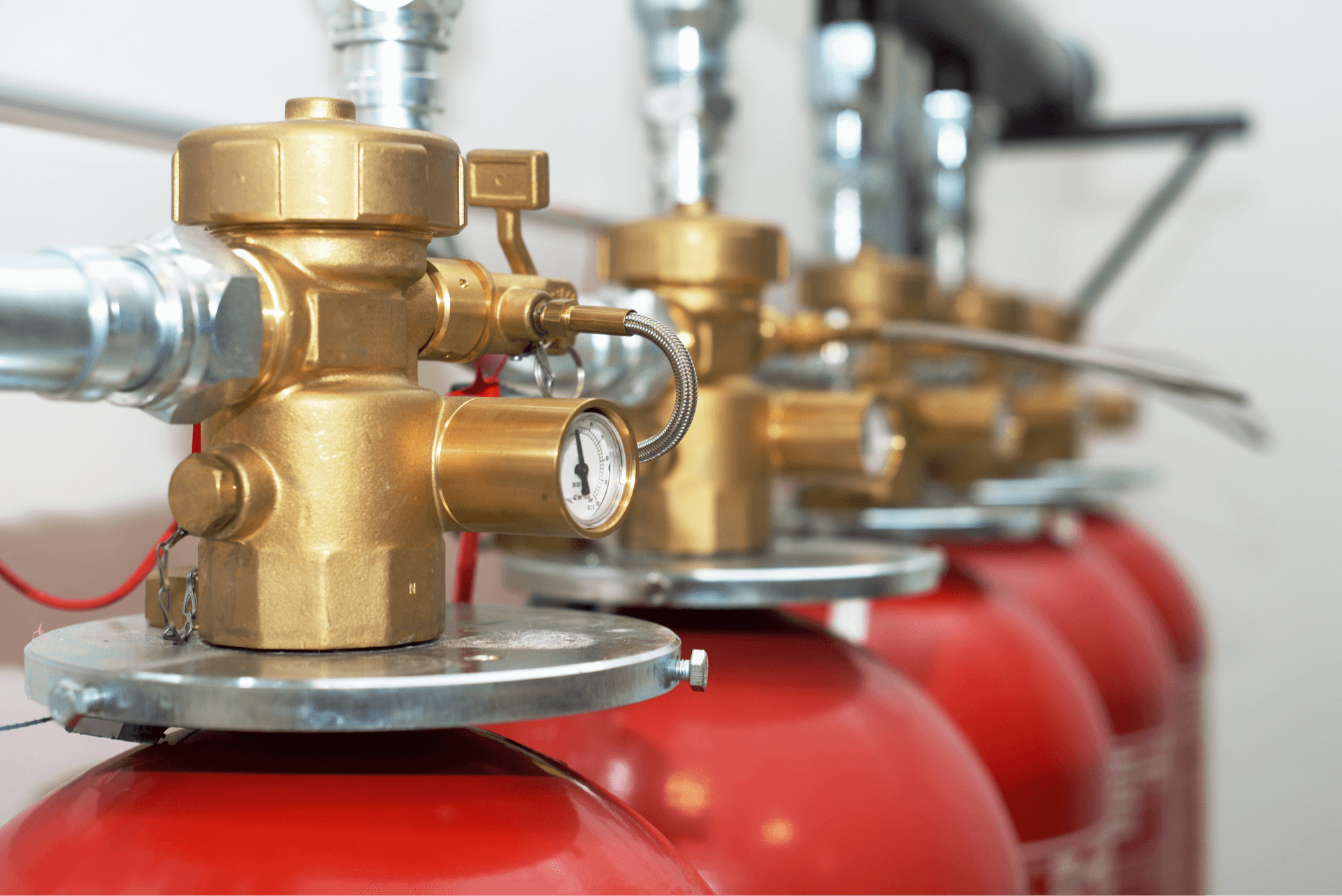

WHAT IS INSPECTED?

When an inert gas fire suppression system is inspected, the system itself is the first priority. Does it meet all requirements? Are any parts in need of replacement? Moreover, an annual inspection of your inert gas fire suppression system is required by Dutch law. Inert gas cylinders should be subjected to pressure testing once per 10 years and after use. For this pressure test, the gas cylinders should first be emptied, only to be refilled with inert gas after the test.

MAINTENANCE AND REFILLING

INERT GAS

In addition to the inspection and certification of inert gas fire suppression systems, you will also have to deal with maintenance. This comes into play when an inspection shows that certain parts no longer meet the requirements. Preventive maintenance can also be performed between inspections. Maintenance and inspections always have the objective of ensuring safety and increasing the lifespan of your inert gas fire suppression system.

Inert gas cylinders need to be tested and refilled after use, or if the inert gas is older than 10 years. Kenbri Fire Fighting is specialised in refilling inert gas. We are the place to go for refills of the following inert gases: Novec1230, FM200, FE36 and CO2.

TotalCare whitepaper